Applications

Thermal conversion processes

Processing and refining biomass into products that can be used for energy and/or materials, e.g. fuels.

read more

Pyrolysis

Thermal conversion process of organic compounds without oxygen.

read more

Hydrogen generation/production

Thermal conversion process for the production of hydrogen.

read more

Heat treatment

Heat treatment can be used to set the final properties of the component and surface, such as hardness, strength or conductivity.

read more

Debinding ceramics & metals

Debinding removes the binders with their organic components from the green compact.

read more

Hardening / Annealing

Hardening can be used to improve the mechanical resistance of metallic materials by selectively changing and transforming their microstructures.

read more

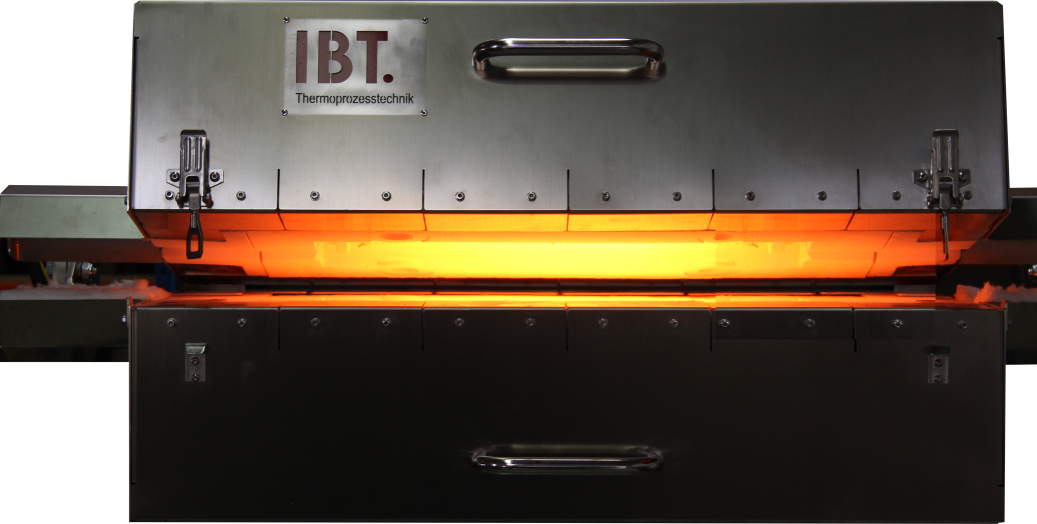

Spectrum plant data

Plant data:

- Working tube & volume according to process requirement

- Working tube arranged vertically or horizontally

- Temperatures up to 1800 °C

- Operation under vacuum, protective or forming gas

- Folding mechanism for exchange of working tubes

- Working tube static or as rotary tube

Design:

- Made of stainless steel or mild steel with coloring

- Wall structure:

- → Working tube

- → Heating elements

- → Radiation shields/ thermal insulation

- → Stainless steel sheeting

- Control cabinet separate or integrated in the rack

Measurement, control & regulation technology:

- Siemens PLC, industrial PC or industrial controller

- Control of power according to process temperatures

- Temperature measurement by thermocouples and pyrometer

- Single or multi-zone control of the heating elements

- Running of the process in program segments (ramps, holding times, change of atmosphere etc.)

- Documentation of process data for quality assurance

Ingolf Jaeger

Head of Sales

Dipl.-Ing. Mechanical Engineering

E-Mail: i.jaeger@ibt.de

Phone.: +49 (0) 3731 1683-15