Applications

Debinding ceramics & metals

Debinding removes the binders with their organic components from the green compact.

read more

Ceramics sintering

Sintering of ceramics, after debinding or shaping by means of additive manufacturing, pressing, or casting.

read more

Sintering metals

Sintering of metals, after debinding or shaping by means of additive manufacturing, pressing, or casting.

read more

Heat treatment

Heat treatment can be used to set the final properties of the component and surface, such as hardness, strength or conductivity.

read more

Vacuum and process gas brazing

Brazing processes place high demands on the furnace technology to ensure the surface quality of the components to be joined.

read more

Hardening / Annealing

Hardening can be used to improve the mechanical resistance of metallic materials by selectively changing and transforming their microstructures.

read more

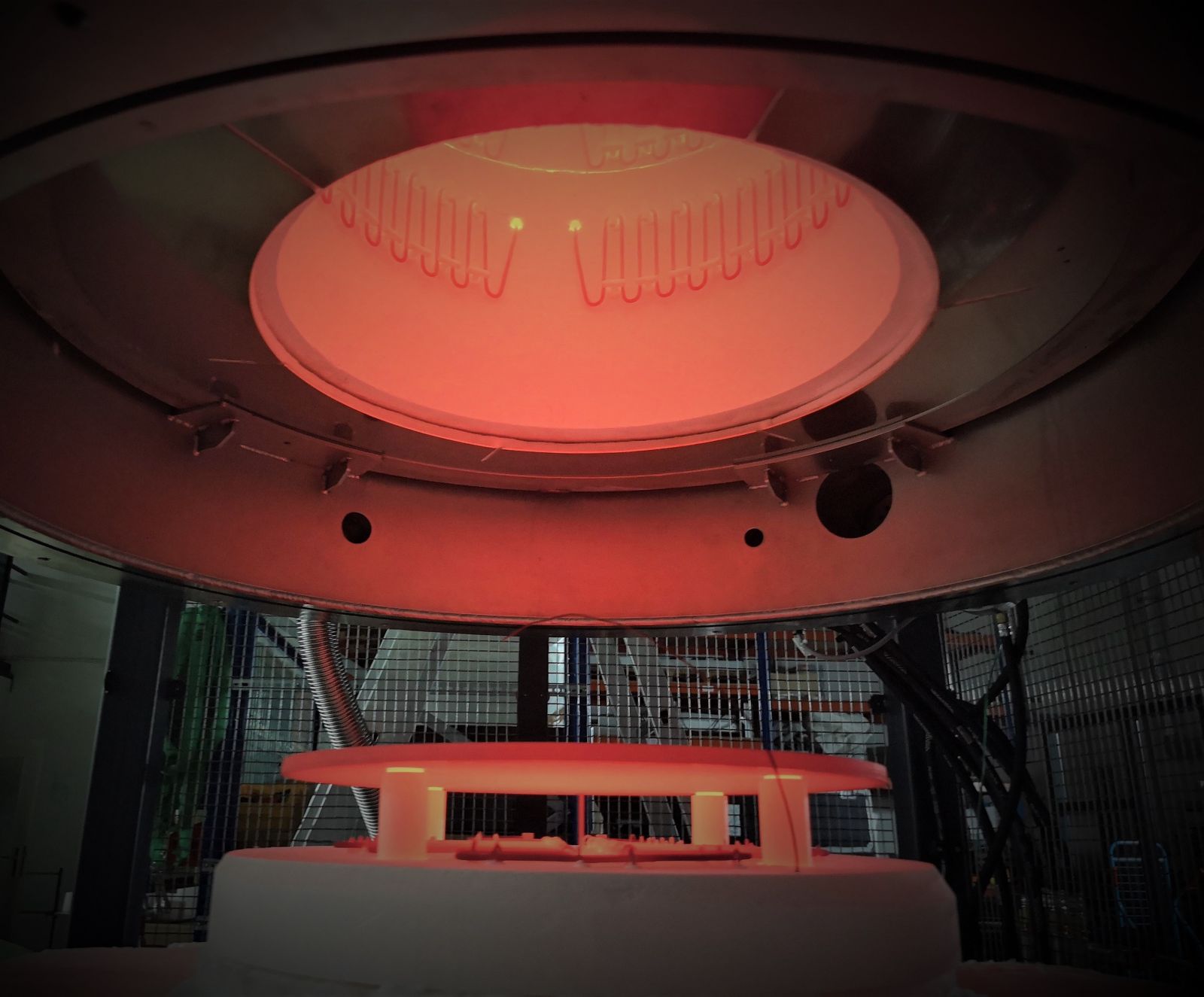

Spectrum plant data

Plant data:

- Temperatures up to 3000 °C

- Useful volume according to requirement

- Vacuum: up to 1*10-6 mbar

- Rotary vane and turbomolecular pump

- Operation under vacuum, protective or reaction gas

- Technical afterburning

- Design as laboratory furnace

Design:

- Frame made of mild steel surface treated or stainless steel

- Stainless steel vessel (double-walled, water-cooled), optional: pressure vessel

- Heating elements according to process requirements

- High temperature insulation or radiation shields

- Control cabinet integrated on the rack

- Vacuum pumping station integrated

Measurement, control & regulation technology:

- Siemens PLC, industrial PC or industrial controller

- Control of power according to process temperatures

- Temperature measurement by thermocouples and pyrometer

- Single or multi-zone control of the heating elements

- Running of the process in program segments (ramps, holding times, change of atmosphere etc.)

- Documentation of process data for quality assurance

Ingolf Jaeger

Head of Sales

Dipl.-Ing. Mechanical Engineering

E-Mail: i.jaeger@ibt.de

Phone.: +49 (0) 3731 1683-15