THT-Tailored Heating Technologie

The significant reduction of CO2 emissions is a major goal for society in the coming decades. Consistent lightweight construction in the automotive and aerospace industries is contributing to the achievement of this goal. The high demand for lightweight components leads to high prices for carbon fibre semi-finished products and their carbon fibres. Consequently, these fibres should only be used where their outstanding material properties are also needed. Tailored blanks made from organotapes embody intelligent lightweight construction through load-path-oriented orientation of the fibres in combination with a high degree of automation, for example through Automated Fiber Placement (AFP). Due to the load-oriented fibre orientation, a tailored blank typically has varying sheet thicknesses and numbers of layers over the surface. The consolidated, flat tailored blank is heated to forming temperature before thermoforming. The varying wall thickness causes an inhomogeneous temperature distribution. The so-called hot spots (local overheating), in areas with low wall thicknesses, lead to degradation of the thermoplastic matrix and delamination of the fibre-reinforced plastic. The cold spots, on the other hand, lead to poor surface qualities, insufficient forming and poor dimensional accuracy of the end product.

THT-Tailored Heating Technology for Fibre Plastic Composites

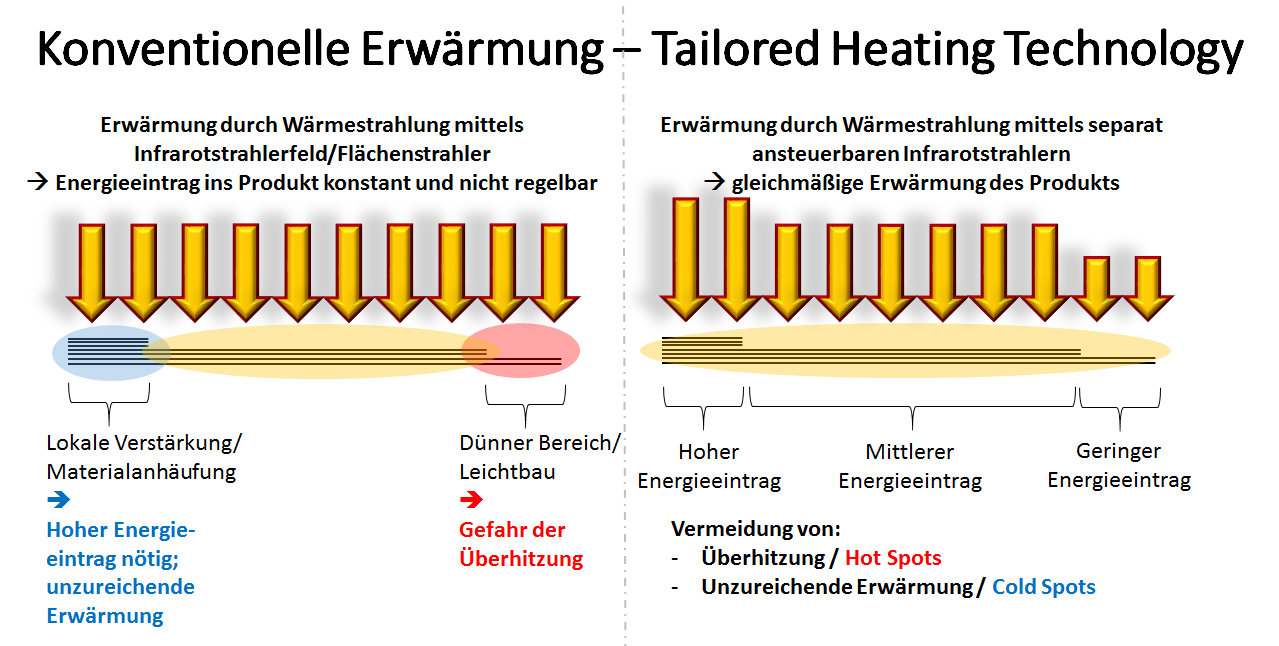

To avoid this problem, IBT uses the new process development Tailored Heating Technology (THT) for homogeneous heating of the tailored blanks in its ThermoLine-HEAT batch furnace, which is already established on the market. In contrast to current systems, the approach of THT is to vary or adapt the heat input locally according to the material thickness. The following figure shows both the typical material accumulation in tailored blanks and the advantages of the new technology compared to existing heating techniques.

In this way, areas of thin sheet thickness are not unnecessarily overheated and areas of heavy material accumulation are only sufficiently heated to forming temperature. This is achieved by a two-dimensional pixel matrix of infrared spot emitters. The THT thus results in higher process reliability, greater flexibility during product changes and lower reject rates by avoiding hot and cold spots.

In principle, IR heating systems can be very finely controlled and regulated, as the IR emitters are much more responsive than comparable convective systems. In addition to the possibility of varying the energy input locally, the selection of the appropriate infrared emitter is equally decisive for high product quality. In general, heat emitters are divided into short-wave, (fast) medium-wave and long-wave infrared on the basis of the emission spectrum. The suitable emitter can also be assigned to corresponding material classes and their absorption spectra via this property. Electromagnetic radiation in the wavelength range of the absorption maxima of the materials (resonance effect) reduces heat loss to a minimum. Under certain circumstances, the choice of emitter is made on the basis of individual requirements of the intended process, such as particularly rapid heating (high power density), the reaction speed or penetration depths (heating through the component or heat input limited to the surface). In order to meet the most diverse requirements, IBT draws on the entire spectrum of different types of emitters and uses them as needed.

The relevant manufacturers of infrared emitters have suitable know-how to fully develop the procedural process with the plant operator. However, infrared emitter manufacturers usually only specialise in one or two emitter types and do not offer the entire portfolio. At this point, the conflict of interests between the emitter manufacturer, the plant builder and the plant operator is pre-programmed. Often, the required thermal process is adapted to an existing emitter type, which means that the heat treatment process does not utilise the full potential of infrared technology. The thermal process with its special requirements necessitates the manufacturer-independent selection of the most suitable infrared emitter depending on the materials to be treated and the exposure time.

Dr. Eder: "In order to meet the requirements of plant operators and processes, IBT is able to draw on the entire spectrum of different types of emitters and use the required emission behaviour as needed to improve quality while saving energy. In particular, the flexible selection of infrared emitters offers extended possibilities for production cycles that are difficult to control in terms of heat technology."

If all the parameters are right, efficiency and process reliability increase and rejects decrease. IBT GmbH from Freiberg is an established manufacturer of infrared plant technology and a specialist in infrared radiant heat. IBT acts as a complete service provider from system planning to installation and after-sales service.

Ingolf Jaeger

Head of Sales

Dipl.-Ing. Mechanical Engineering

E-Mail: i.jaeger@ibt.de

Phone.: +49 (0) 3731 1683-15